Start your egg incubator manual by unboxing your incubator and checking all parts, including incubator accessories like the egg turner and fan. Place the incubator on a level surface away from sunlight and drafts for stable poultry incubation. Calibrate temperature and humidity sensors at egg height, using double readings for accuracy. Preheat the incubator for 24–48 hours, then load chicken, ducks, or poultry eggs with the large end up. Track batches and avoid moving eggs after initial setup. Monitor daily, adjust humidity and temperature, and follow tips for raising healthy chicks.

Tip:

Use this table to avoid common chicken incubation mistakes:

| Common Error | Correct Approach | Incorrect Approach |

|---|---|---|

| Incubator Access | Keep closed during lockdown | Open during lockdown |

| Humidity Level | Maintain 65–75% | Drop below 60% |

| Egg Handling | Do not handle | Move or turn eggs |

Clean and disinfect the eggs incubator manual after hatching. Store the manual and incubator in a dry area for the next poultry raising cycle.

Key Takeaways

- Unbox and check all parts of your incubator before use. Ensure it is on a level surface away from sunlight and drafts for stable conditions.

- Calibrate temperature and humidity sensors at egg height. Preheat the incubator for 24–48 hours before adding eggs to stabilize the environment.

- Maintain humidity levels between 45–55% for the first 18 days, then raise to 65–70% for the last three days to support healthy chick development.

- Turn eggs 3 to 5 times daily to prevent embryos from sticking to the shell. Stop turning three days before hatching to allow chicks to position themselves.

- After hatching, clean and disinfect the incubator thoroughly. Store it in a dry place to prepare for the next incubation cycle.

Safety First—Egg Incubator Manual

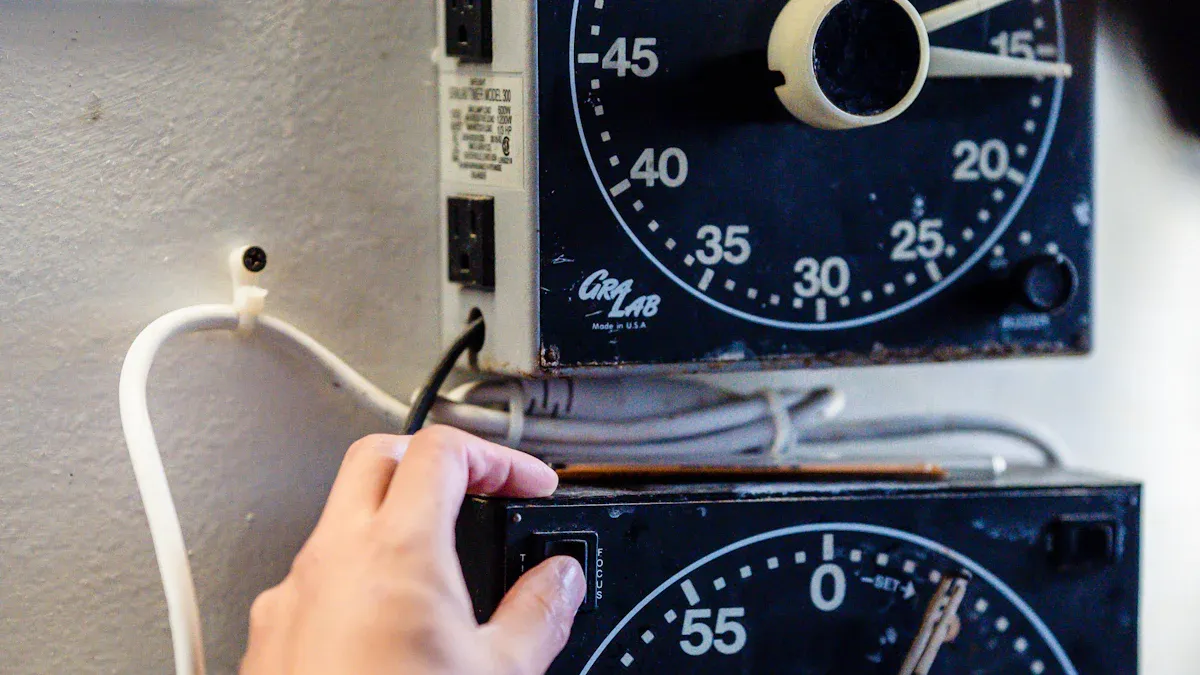

Electrical Safety Precautions

You must check the power cord and plug before you use your egg incubator manual. Make sure the cord is not damaged or frayed. Plug the incubator into a grounded outlet. Avoid using extension cords because they can cause overheating. Place the incubator away from water sources to prevent electric shock. If you see sparks or smell burning, unplug the incubator right away. Look for safety certifications when you buy an incubator. The Safe Quality Food (SQF) Program is a global standard that helps keep food and equipment safe.

| Certification | Description |

|---|---|

| SQF | The Safe Quality Food (SQF) Program is a rigorous and credible food safety and quality program recognized globally, designed to meet industry, customer, and regulatory requirements for all sectors of the food supply chain. |

Heat Protection Measures

Egg incubators create heat to help chicks grow. You should keep your hands away from heating elements inside the incubator. Wait until the incubator cools down before cleaning or moving it. Place sensors at egg height and away from direct heat. This helps you get accurate readings and keeps eggs safe. Use double sensors if possible to check temperature. Fresh air and correct humidity levels are vital for developing chicks. A clean and disinfected environment helps prevent infections. Some incubators use bacteria growth inhibiting technology to improve hatch rates.

Tip:

Always adjust humidity by changing the water surface area, not just by adding more water. Use a sponge or cloth strip to increase evaporation if needed.

Child & Pet Safety Tips

You should keep the eggs incubator manual out of reach of children and pets. Place the incubator on a stable table or shelf. Do not let children open the lid or touch the controls. Pets can knock over the incubator or chew on cords. Always supervise young helpers. Teach them to wash hands before and after handling eggs. A safe setup protects both your family and your chicks.

Incubator Types & Basics—Complete Guide to Incubation

Forced-Air vs Still-Air Incubators

When you start with poultry incubation, you need to know the difference between forced-air and still-air incubators. Forced-air incubators use a fan to move air around the eggs. This design keeps the temperature even and helps oxygen reach every egg. Still-air incubators do not have a fan. They rely on natural air movement, which can cause hot and cold spots inside the incubator.

- Forced-air incubators usually give you better hatch rates for chicken and other poultry eggs.

- Still-air incubators may have lower hatch rates because the temperature is not always the same everywhere inside.

If you want the best results for chicken or poultry hatching, many experts recommend forced-air incubators. When choosing an incubator, think about the type of poultry you want to hatch and how much control you need over the environment.

Temperature Zones and Airflow

Temperature control is very important for chicken incubation. Forced-air incubators keep the temperature steady at 99.5°F (37.5°C) everywhere inside. Still-air incubators need you to check the temperature at the top of the eggs. For chicken eggs, keep the top layer at 101–102°F (38.3–38.9°C). If you use a still-air incubator, you must watch for temperature changes in different spots.

- Forced-air incubators reduce hot and cold spots by moving air all the time.

- Still-air incubators can have uneven heat, so you need to check more often.

Tip:

Place your thermometer at the same height as your chicken eggs. Keep it away from the heater to get the most accurate reading.

Understanding Air Circulation

Airflow helps keep the right temperature and humidity for poultry eggs. Forced-air incubators use fans to move air, which helps all chicken eggs get the same amount of heat and oxygen. This design also makes it easier to control humidity during incubation. Still-air incubators depend on natural air movement, so you may see more temperature swings.

- Good airflow in forced-air incubators improves heat exchange and keeps the environment stable for chicken and other poultry.

- Still-air incubators need you to check for uneven heat and adjust as needed.

You can use this complete guide to incubation to help you decide which incubator fits your poultry hatching needs. Always record your results and make small changes to improve your chicken hatch rates.

Unboxing & Placement—Eggs Incubator Manual

Level Surface and Stable Setup

You should place your incubator on a flat, sturdy table or shelf. A level surface keeps the incubator steady and prevents eggs from rolling. Make sure the area does not shake or vibrate. This helps you maintain even temperature and humidity during incubation. Put sensors at the same height as the eggs and away from direct heat. Use two sensors if possible to check readings. Always keep the incubator manual nearby for quick reference.

Tip:

Place the incubator where children and pets cannot reach. This keeps your setup safe and prevents accidents.

Avoiding Sunlight and Drafts

Direct sunlight can cause temperature spikes inside incubators. You should keep the incubator away from windows and bright lights. Drafts from air conditioners or heaters can lower humidity and make the temperature unstable. Choose a spot far from vents and doors. Stable air helps you control the incubation process and improves hatch rates.

Ideal Room Conditions for Incubation

Incubators work best indoors where you can control the environment. Good ventilation brings fresh air but do not place the incubator in a drafty spot. Keep the room temperature steady, between 68–75°F (20–24°C). Humidity should stay at 45–55% for the first 18 days and rise to 65–70% for the last three days. Use a shallow pan or a damp sponge to adjust humidity. If the room temperature changes often, you may see problems with embryo growth and hatch rates.

| Parameter | Effect of Temperature Fluctuation |

|---|---|

| Albumen-weight to egg-weight ratio (AR) | Delay and reduction in expected drop |

| Yolk-weight to egg-weight ratio (YR) | Lower nutrient consumption |

| Embryo-weight to egg-weight ratio (ER) | Slower growth and lower than normal |

| Heart rate (HR) | Elevated under stress |

| Voluntary movements per minute (VMM) | Decreased under stress |

| Mortality rates | Higher during first four days |

| Malformation prevalence | Increased with high temperatures |

You can improve incubation results by keeping the room stable and following these guidelines. Record your settings and make small changes as needed. Incubators perform best when you avoid sudden changes in temperature and humidity.

Instruments & Calibration—Egg Incubator Manual

Calibrating Thermometers and Hygrometers

You need accurate instruments to keep your incubators working well. Before testing the incubator, check your thermometer and hygrometer. Most common thermometers show a range of ±2°F, while medical thermometers can be much more precise at ±0.2°F. Use a glass thermometer for calibration. Place the bulb close to the incubator’s sensors. Let the incubator run for at least 24 hours before you adjust any readings. This helps you set the right temperature and humidity for successful incubation.

| Device Type | Accuracy Range |

|---|---|

| Common Thermometers | ± 2°F |

| Medical Thermometers | ± 0.2°F |

Tip:

Always calibrate your thermometer and hygrometer before each batch. Reliable readings help you avoid problems with embryo development.

Probe Placement and Height

You should place probes at the same height as the eggs inside your incubator. This gives you the most accurate readings for incubation. Keep probes away from direct heat sources. If you use forced-air incubators, place probes near the center. For still-air incubators, position probes at the top layer of eggs. This matches the temperature zones needed for healthy chick growth.

- Place sensors at egg height.

- Avoid placing probes under heating elements.

- Use two sensors if possible to compare results.

Safety Note:

Always handle probes gently. Damaged sensors can give false readings and affect hatch rates.

Double-Checking Sensor Readings

You should double-check sensor readings to make sure your incubators stay reliable. Use two thermometers and two hygrometers if you can. Compare their readings every day. If you see a difference, use the more accurate device or recalibrate. Accurate data helps you control temperature and humidity during incubation. This leads to better hatch rates and healthier chicks.

| Calibration Aspect | Importance |

|---|---|

| Temperature Accuracy | Ensures incubator settings match actual temperature, crucial for embryo development. |

| Humidity Control | Maintains proper moisture levels, preventing issues like excessive moisture loss or bacterial growth. |

| Uniformity | Ensures consistent conditions throughout the incubator, leading to even development among eggs. |

| Hatchability | Directly influences hatch rates and chick health; optimal conditions are essential. |

| Quality of Chicks | Supports normal growth and reduces deformities or health issues in hatched chicks. |

| Economic Impact | Optimizes hatchery operations, leading to higher hatch rates and reduced production costs. |

| Data Accuracy | Maintains accuracy in monitoring temperature and humidity, aiding informed decision-making. |

| Risk Mitigation | Identifies potential issues early, preventing negative impacts on hatchery performance. |

Tip:

Record your readings daily. This helps you spot changes early and adjust your incubator settings for the best results.

Warm-Up & Baselines—Complete Guide to Incubation

Forced-Air Baseline Settings

You should always start by preheating your forced-air incubator. Run the incubator empty for 24–48 hours before adding eggs. This step helps you stabilize the temperature and humidity. Forced-air incubators use a fan to keep the air moving, so you get even heat around every egg.

Set your temperature to 99.5°F (37.5°C). Place your thermometer at the same height as the eggs, away from direct heat. For chicken eggs, keep humidity at 45–55% for the first 18 days. Raise humidity to 65–70% during the last three days before hatching. Use a shallow pan or a damp sponge to adjust humidity. Increase the water surface area if you need higher humidity.

| Setting | Value |

|---|---|

| Temperature | 99.5°F (37.5°C) |

| Humidity (Days 1–18) | 45–55% RH |

| Humidity (Last 3 Days) | 65–70% RH |

Tip:

Always use two thermometers or hygrometers to double-check your readings. Place sensors at egg height and away from the heater.

You should also check the room conditions. Keep the incubator away from direct sunlight and drafts. Stable room temperature helps you maintain the right environment inside.

Still-Air Baseline Adjustments

Still-air incubators do not have a fan. The air inside stays still, so heat rises to the top. You must measure the temperature at the top of the eggs, not in the middle or bottom. Set your thermometer at egg height.

For still-air incubators, aim for 101–102°F (38.3–38.9°C) at the top of the eggs. This setting helps you reach the right temperature at the center of each egg. Use the same humidity levels as forced-air: 45–55% for the first 18 days, then 65–70% for the last three days.

| Incubator Type | Temperature at Egg Top | Humidity (Days 1–18) | Humidity (Last 3 Days) |

|---|---|---|---|

| Still-Air | 101–102°F (38.3–38.9°C) | 45–55% RH | 65–70% RH |

Note:

Always avoid placing eggs directly under the heating element. Make sure air can flow between eggs for even warming.

You should record your settings and check them daily. If you see changes, adjust the water surface or ventilation. Careful setup and monitoring help you get the best hatch results.

Preloading Eggs—Eggs Incubator Manual

Storing Eggs Before Incubation

You need to store eggs carefully before you start incubating hatching eggs. Keep eggs in a cool place at 53–59°F (12–15°C) with humidity between 75% and 85%. Always place eggs with the pointy end down and the large end up. Turn eggs once a day to stop the yolk from sticking to the shell. Do not store eggs for more than seven days because the chance of hatching drops after that. Collect eggs at least twice a day, especially when it is hot. Use only clean eggs and avoid washing them unless you must. If you need to clean an egg, use warm water and never use cracked or misshapen eggs. Proper storage keeps eggs fresh and helps embryos stay healthy.

Tip:

Store eggs in a carton or tray that lets air move around each egg. This helps keep the temperature and humidity even.

Resting, Batch Numbering, and Stability

After you receive eggs, let them rest for 12–24 hours before you start incubation. This helps the air cell inside each egg settle. Write a batch number on each egg or tray so you can track which eggs go into the incubator together. Change the angle of stored eggs a little each day to keep the yolk from sticking. Stable storage conditions help you get better hatch rates. If you order eggs by mail, resting is even more important because it gives the eggs time to recover from travel.

| Step | Why It Matters |

|---|---|

| Rest eggs 12–24 hrs | Stabilizes air cell |

| Batch numbering | Tracks hatch results |

| Angle change daily | Prevents yolk sticking |

Egg Positioning and Airflow Considerations

When you load eggs into the incubator, place them at the same height and avoid putting any eggs directly under the heating element. Make sure there is space between eggs so air can flow around each one. Balanced placement helps every egg get the same amount of heat and oxygen. If you crowd eggs or stack them unevenly, some eggs may get too hot or too cold. Good airflow keeps embryos growing at the same rate and helps chicks hatch together. Eggs near the central fan get better air speed and heat transfer, which is important for healthy development.

Note:

Always check that eggs are level and spaced evenly. Symmetrical placement supports even airflow and temperature.

Daily Operation—Egg Incubator Manual

Temperature Control and Adjustments

You need to check the temperature inside your incubators every day. Stable temperature helps chicken, ducks, and other poultry embryos grow strong. Forced-air incubators work best at 99.5°F (37.5°C). Still-air incubators need you to measure at the top of the eggs, aiming for 101–102°F (38.3–38.9°C). Place your sensors at egg height and away from heating elements. Double-check readings with two thermometers for accuracy.

If you see the temperature drop or rise, adjust the settings using your incubator accessories. Most incubators have a digital display or a manual dial for adjusting temperature. Always make small changes and wait for the incubator to stabilize before checking again. Sudden changes can stress chicken embryos and lower hatch rates.

Tip:

Record temperature readings at the same time each day. This helps you spot patterns and fix problems early.

If you experience a power outage, keep the incubator closed. Wrap it with dry towels and place warm water bottles inside to hold heat. When power returns, restore the settings slowly to avoid shocking the hatching eggs.

Humidity Control Techniques

Humidity plays a big role in hatching eggs successfully. You want to keep humidity between 45–55% RH for the first 18 days. Raise humidity to 65–70% RH during the last three days before chicks hatch. Use water trays to add moisture. Fill more trays to increase humidity or remove some to lower it. Damp sponges or cloth strips can help control moisture levels.

Here are some effective humidity control methods:

- Fill water trays to increase humidity through evaporation.

- Use damp sponges instead of water for finer control.

- Reduce the number of filled trays to lower humidity.

- Increase airflow to let moisture escape.

- Monitor ambient room conditions and adjust settings as needed.

- Track egg weight loss to make sure eggs lose about 13–15% by hatch day.

| Method | Description |

|---|---|

| Water Trays | Filling trays with water increases humidity through evaporation. |

| Automated Humidity Control | Systems that automatically adjust humidity levels based on set parameters. |

| Monitoring Ambient Conditions | Adjusting settings based on the humidity of the surrounding environment. |

| Weighing Eggs | Tracking weight loss of eggs to ensure proper humidity levels are maintained. |

| Ventilation | Controlling airflow to manage humidity levels effectively. |

| Evaporating Blocks | Adding blocks to help maintain humidity stability during hatching. |

High humidity during hatching helps chicks break out of their shells. If humidity gets too high, chicks may drown or have trouble hatching. If humidity is too low, chicks can stick to the shell. Always adjust humidity by changing the water surface area, not just by adding more water.

Tip:

Use a shallow pan or a wet sponge to quickly raise humidity during the last three days. Good ventilation supports healthy embryo development and chick quality.

Turning Eggs: Frequency and Method

Turning hatching eggs is important for raising healthy chicken, ducks, and other poultry. You need to turn eggs at least three times a day. Five times a day is better. Many automatic turners rotate eggs every hour, which gives the best results. Turning prevents the embryo from sticking to the shell and helps chicks develop evenly.

- Turn eggs three to five times daily.

- Rotate eggs at least 90° each time.

- Stop turning eggs three days before hatching begins.

“An egg turning frequency of 24 times per day during incubation provided high hatchability rates. In contrast, the turning frequencies of 12, 6, and 3 times per day showed significant losses in hatchability.”

If you use a manual turner, mark one side of each egg with a pencil. This helps you keep track of which eggs you have turned. Always wash your hands before handling eggs to protect the embryos. Automatic turners save time and help you follow the operating instructions in your eggs incubator manual.

Proper turning supports even development for chicken, ducks, and other poultry. Chicks hatch stronger and healthier when you follow these steps. Stop turning eggs three days before hatching to let chicks position themselves for breaking out of the shell.

Note:

Always check that eggs are stable after turning. Uneven placement can affect airflow and temperature.

Airflow and Vent Management

Airflow plays a big role in keeping your eggs healthy during incubation. You need to manage vents and air movement to control temperature, humidity, and oxygen levels. Good airflow helps every embryo get enough fresh air and keeps the environment stable.

Why Airflow Matters

- Air brings oxygen to growing embryos.

- Air removes carbon dioxide and extra moisture.

- Air helps keep temperature and humidity even inside the incubator.

If you use a forced-air incubator, a fan moves air around the eggs. This keeps the temperature steady at 99.5°F (37.5°C). Still-air incubators do not have a fan, so you must check the temperature at the top of the eggs. Aim for 101–102°F (38.3–38.9°C) at the egg tops.

How to Manage Vents

You control airflow by opening or closing vents. Most incubators have adjustable vents on the top or sides. You should start with vents partly open. As embryos grow, they need more oxygen. Open the vents a little more each week. During the last three days, keep vents open for good airflow, but avoid opening the lid unless you must.

Tip:

Always keep the incubator away from direct sunlight and drafts. Stable room conditions help you control airflow and keep eggs safe.

Steps for Good Airflow

- Place eggs at the same height and leave space between them.

- Avoid putting eggs right under the heating element.

- Check that air can move around each egg.

- Adjust vents as embryos grow. Open them wider after day 14.

- Use two sensors at egg height to check temperature and humidity.

- Record changes in airflow and vent settings in your logbook.

Vent Management Table

| Stage of Incubation | Vent Position | Reason |

|---|---|---|

| Days 1–7 | Slightly open | Lower oxygen need |

| Days 8–14 | Half open | Embryos growing fast |

| Days 15–18 | Mostly open | High oxygen demand |

| Last 3 days (hatch) | Fully open | Chicks need fresh air |

Safety and Practical Tips

Note:

Place sensors at egg height, away from direct heat. Use two sensors to check readings.

Adjust humidity by changing water surface area, not just adding water.

During a power outage, keep the incubator closed. Wrap it with dry towels and use warm water bottles to hold heat. Restore settings slowly when power returns.

Common Airflow Problems and Solutions

- If humidity drops too low, close vents slightly or add a damp sponge.

- If humidity gets too high, open vents wider or reduce water surface area.

- If eggs lose weight too fast, raise humidity or close vents a bit.

- If eggs lose weight too slowly, lower humidity or open vents more.

Checklist for Airflow and Vent Management

- Check vent position daily.

- Record any changes in your logbook.

- Watch for condensation or dry spots inside the incubator.

- Increase ventilation as embryos grow.

- Keep lid closed during hatching except for emergencies.

You can improve hatch rates by managing airflow and vents carefully. Always observe, record, and adjust as needed. Good airflow supports healthy chicks and a successful hatch.

Monitoring & Candling—Complete Guide to Incubation

Candling Schedule and Timing

You need to candle eggs at specific times during incubation to check their progress. Candling means shining a light through the egg to see what is happening inside. You should follow a schedule to get the best results. Use this table to guide your candling sessions:

| Candling Session | Day | Purpose |

|---|---|---|

| First Candling | 1 | Check for yolk, air cell, cracks, double yolks, mottling, blood spots |

| Second Candling | 7 or 10 | Monitor embryo development and discard undeveloped eggs |

| Third Candling | 14 or 18 | Final check before lockdown, assess air cell sizes and egg weights |

You should always candle in a dark room and handle eggs gently. Mark eggs that show problems so you can remove them later.

Tip:

Candle eggs quickly to avoid cooling them. Always wash your hands before and after handling eggs.

Interpreting Candling Results

When you candle eggs, you look for signs of healthy growth. You can spot problems early and improve your hatch rates. Here are some things you might see:

- Fertility Assessment: You can identify infertile eggs and remove them from incubation.

- Early Mortality Detection: You can find eggs with embryos that died early and prevent contamination.

- Chick Quality Improvement: Removing non-viable eggs helps you get healthier chicks.

- Genetic Issues: You may notice patterns of early death or low fertility, which can point to genetic problems.

- Viability Check: You can see if a chick is growing, if the egg is empty, or if it is rotten.

- Developmental Issues: You can spot signs that a chick stopped developing or is not growing well.

You should record your findings in a notebook. Tracking results helps you adjust your incubation process for better outcomes.

Weight Loss and Moisture Tracking

Eggs lose weight during incubation as moisture leaves through the shell. You need to track this weight loss to make sure conditions stay right. Most eggs lose about 10–12% of their weight by day 18. Smaller eggs lose a higher percentage than larger eggs. If eggs lose too much weight, humidity may be too low. If they lose too little, humidity may be too high.

- Egg weight loss during incubation usually ranges from 3.27% to 11.32%.

- Average loss is about 11.25% at 18 days.

- Optimal hatch rates happen when eggs lose 10–12% of their weight.

You should weigh a sample batch at the start and again at day 18. Adjust humidity based on your results. Combine weight loss data with air cell size to fine-tune your settings.

Note:

Always use a scale that measures in grams for accuracy. Record weights and humidity readings for each batch.

Lockdown & Hatch—Eggs Incubator Manual

Preparing for the Last Three Days

You have reached the final stage of incubation. The last three days are called "lockdown." You must prepare your eggs incubator manual for hatching eggs by following these steps:

- Stop turning the hatching eggs at day 18. Make sure the large end faces up.

- Set the temperature to 100.5°F (38°C). Keep sensors at egg height and away from direct heat.

- Raise humidity to 70% RH. Use a shallow pan or a damp sponge to increase water surface area.

These steps help the chicks get ready for hatching. You should check the temperature and humidity twice a day. Record your readings in your logbook. Stable conditions help you avoid problems and support raising baby chicks.

Tip:

Place eggs at the same height and leave space between them. Good airflow helps every chick hatch safely.

Stopping Turning and Raising Humidity

You must stop turning hatching eggs during lockdown. Chicks need time to position themselves for hatching. If you keep turning, you may harm the chicks or delay their progress. Raising humidity is very important at this stage.

The purpose of ‘Lockdown’ is to provide conditions to enable the chick to hatch. Once a hole and/or pip has been made in the shell then there is a risk of premature drying of the membranes and the higher humidity prevents this happening. Raising the humidity before this time can only be justified if the egg has lost too much weight and further moisture loss needs to be prevented.

If you do not manage humidity, chicks may have trouble breaking out of their shells. Too little moisture can cause the membranes to dry out. Too much moisture can lead to late deaths before internal pipping. You must balance humidity to help every chick complete hatching eggs successfully.

Lid Opening Precautions During Hatch

During hatching, you need to keep the incubator lid closed as much as possible. Opening the lid can cause temperature and humidity to drop quickly. Chicks need a warm and moist environment to finish hatching eggs. Only open the lid if you see a chick stuck or in distress.

- Check through the viewing window instead of lifting the lid.

- Open the lid briefly and only when necessary.

- Prepare a warm towel to cover the opening if you must intervene.

Note:

Good ventilation is important, but avoid drafts. Stable conditions help chicks hatch together and reduce stress.

You can improve hatch rates by following these steps in your eggs incubator manual. Careful monitoring and gentle handling help you raise healthy chicks and enjoy the process of raising baby chicks.

Troubleshooting—Egg Incubator Manual

Temperature Fluctuations and Solutions

You may notice temperature changes inside your incubator during incubation. These changes can affect chicken, ducks, and other poultry hatching eggs. Temperature swings often happen because of room conditions, sensor problems, or equipment issues. You need to keep the temperature steady for healthy chicks.

Here is a table that shows common temperature problems, reasons, and solutions:

| Problem | Possible Reasons | Solutions |

|---|---|---|

| Unstable Incubation Temperature | Environmental issues, temperature control failure, sensor damage or displacement | Choose a suitable location, calibrate the temperature sensor regularly, check the equipment and contact maintenance |

You should place your incubator away from direct sunlight, air conditioners, and heaters. Always put sensors at egg height and away from heating elements. Use two thermometers to check readings. If you see a big difference, recalibrate your sensors. Record temperature every day and adjust settings slowly. Sudden changes can stress chicken embryos and lower hatch rates.

Tip:

Preheat your incubator for 24–48 hours before loading hatching eggs. This helps you find and fix temperature problems early.

If you have a power outage, keep the incubator closed to hold heat. Wrap it with dry towels or blankets. For longer outages, use battery-powered heaters or a generator. When power returns, restore settings slowly.

Humidity Swings and Corrections

Humidity changes can cause problems for chicken, ducks, and other poultry hatching eggs. You need to keep humidity between 45–55% RH for the first 18 days and raise it to 65–70% RH for the last three days. If humidity swings too much, chicks may stick to the shell or have trouble hatching.

Try these tips to control humidity during incubation:

- Lower water levels by reducing the number of filled trays.

- Use damp sponges for fine moisture control.

- Increase air ventilation by opening vents or adding a small fan.

- Place dry sponges or towels inside to absorb extra moisture.

- Use silica gel packs to soak up excess humidity.

- Add desiccants like activated charcoal or calcium chloride if needed.

- Remove water trays temporarily if humidity gets too high.

Always adjust humidity by changing the water surface area, not just by adding more water. Weigh a sample batch of chicken eggs at the start and again at day 18. Eggs should lose about 12% of their weight by day 18. If eggs lose weight too fast, raise humidity or reduce ventilation. If eggs lose weight too slowly, lower humidity or increase airflow.

Safety Note:

Place sensors at egg height and away from direct heat. Double-check readings with two hygrometers for accuracy.

Air Cell Issues and Adjustments

Air cell problems can affect hatching eggs and chick health. The air cell grows as moisture leaves the egg during incubation. You need to check air cell size when candling chicken, ducks, and other poultry eggs. If the air cell is too small or too large, adjust humidity and ventilation.

You can use these methods to identify air cell issues:

| Methodology | Description |

|---|---|

| Thermal Imaging | Use thermal cameras to detect air cell size quickly by interpreting infrared wavelengths. |

| Deep Learning Algorithms | Combine thermal imaging with deep learning for automated and high-throughput egg assessment. |

If you see sticky chicks or late hatching, check humidity and air cell size. Sticky chicks often mean humidity was too high. You can gently bathe sticky chicks in warm water, but keep them warm and dry. Provide a warm area (99.5°F–100.5°F or 37.5–38°C) and a cooler spot for chicks to rest. Add electrolytes or sugar water to their drinking water to boost energy.

Tip:

Use candling to track air cell growth and egg weight loss. Adjust humidity and ventilation based on your findings.

You should always follow the operating instructions in your eggs incubator manual. Record your settings, results, and any changes you make. Review your notes after each batch to improve your process for raising baby chicks, chicken, ducks, and other poultry.

Sticky Chicks, Late Hatch, and Interventions

Sticky chicks and late hatches can happen even when you follow your egg incubator manual closely. You may see chicks that cannot break free from their shells or have dried membranes stuck to their bodies. These problems often come from humidity issues or temperature swings during incubation.

Why Sticky Chicks Happen

- Humidity stayed too high or too low during incubation.

- Eggs lost too much or too little weight by day 18.

- Air cell size did not match the expected growth.

- You opened the incubator lid too often during hatch.

How to Spot Sticky Chicks

- Chicks look wet or glued to shell pieces.

- Membranes appear dry, tough, or rubbery.

- Chicks struggle to move or breathe after pipping.

Tip:

Always check egg weight loss and air cell size together. Eggs should lose about 12% of their starting weight by day 18. If you see sticky chicks, review your humidity records and adjust for your next batch.

What to Do for Sticky Chicks

- Keep the incubator closed as much as possible during hatch. This keeps humidity stable.

- If you must help, wash your hands and use a warm, damp cloth to gently moisten the dry membrane. Do not pull the chick out quickly.

- Move weak chicks to a warm brooder (99.5–100.5°F, or 37.5–38°C) after they dry off.

- Offer sugar water or electrolytes for extra energy.

Late Hatch Causes and Solutions

Late hatching often means the temperature ran a bit low or the eggs lost too little weight. Sometimes, thicker shells or breed differences cause delays.

| Problem | Possible Cause | What You Can Do |

|---|---|---|

| Late hatch | Low temperature, high humidity, thick shells | Check and calibrate sensors, adjust humidity, record breed notes |

| Weak chicks | Humidity too high, poor ventilation | Improve airflow, adjust water surface area, keep lid closed during hatch |

Safety Note:

Only help a chick if you see it stuck for more than 24 hours after pipping and the membrane looks dry and hard. Use a damp cotton swab to soften the membrane. Never rush or force the chick out.

How to Prevent Sticky Chicks and Late Hatch

- Weigh eggs at the start and day 18. Adjust humidity so eggs lose about 12% of their weight.

- Candle eggs to check air cell growth. Compare with air cell charts.

- Use two sensors at egg height to double-check temperature and humidity.

- Keep room conditions stable. Avoid drafts, direct sunlight, and sudden temperature changes.

- Record every batch. Review your notes and make small changes for next time.

Remember:

Every hatch teaches you something new. Keep good records, review your process, and adjust settings for better results next time.

Power Outage Emergency Steps

A power outage can happen at any time. You need to act fast to protect your eggs and keep the temperature stable. Here is what you should do if the power goes out during incubation:

Immediate Actions

- Keep the incubator lid closed. This helps hold in heat and humidity.

- Wrap the incubator with dry towels or blankets for extra insulation.

- Place warm water bottles (not boiling) around the incubator, but do not let them touch the eggs.

- Move the incubator to the warmest room in your house if possible.

If the Outage Lasts More Than 1–2 Hours

- Replace water bottles with fresh warm ones every hour.

- Check the temperature inside the incubator with a thermometer.

- Do not open the lid unless you must add heat.

Tip:

Prepare an emergency kit with towels, water bottles, and a backup thermometer before you start each batch.

After Power Returns

- Restore the incubator settings slowly. Do not set the temperature too high to "catch up."

- Watch the temperature and humidity closely for the next few hours.

- Record the outage in your logbook. Note how long it lasted and what steps you took.

Table: Power Outage Quick Reference

| Step | What to Do |

|---|---|

| Short outage (<1 hour) | Keep lid closed, insulate with towels |

| Medium outage (1–3 hours) | Add warm water bottles, monitor temperature |

| Long outage (>3 hours) | Consider moving eggs to a pre-warmed backup incubator or use a generator |

Safety Reminder:

Always place sensors at egg height and away from direct heat. Double-check readings after power returns.

How to Prepare for Future Outages

- Test your backup plan before you need it.

- Keep extra towels, water bottles, and a small generator ready.

- Record every emergency and review what worked best.

Note:

You cannot control every emergency, but you can prepare. Careful planning and quick action help you protect your hatch and learn for next time.

Cleaning, Disinfection & Storage—Complete Guide to Incubation

Post-Hatch Cleaning Procedures

After hatching, you need to clean your incubators before starting another round of incubation. Remove all eggshells, membranes, and any leftover material from the trays and surfaces. Use warm water with Dawn dish liquid to wash away dirt and protein buildup. Scrub gently so you do not damage the incubator parts. Rinse everything well to remove soap. Dry all pieces completely before moving to the next step. Cleaning right after hatching helps prevent bacteria from growing and keeps your poultry healthy.

Tip:

Always unplug the incubator before cleaning. Let it cool down to avoid burns.

Disinfection Steps for Safety

Disinfection protects your chicken, chicks, and poultry from harmful germs. After cleaning, choose a safe disinfectant. You can use vinegar to remove dirt and bacteria. Hydrogen peroxide works well to kill bacteria, including Salmonella, and does not leave harmful fumes. A weak bleach solution also helps sanitize trays and surfaces. Soak removable parts in the solution, then rinse and dry them. Some people use commercial disinfectants, but always follow the label instructions. Peroxide is a good alternative to bleach if you want a gentler option. Disinfecting after every hatching cycle keeps your chicken and poultry safe during incubation.

- Vinegar: Removes dirt and bacteria.

- Hydrogen peroxide: Kills bacteria, including Salmonella.

- Bleach solution: Sanitizes trays and surfaces.

- Dawn dish liquid: Cleans with warm water.

- Peroxide: Kills bacteria without strong fumes.

Note:

Wear gloves when using disinfectants. Rinse all parts well before reassembling the incubator.

Proper Storage and Maintenance

Store your incubators in a dry, cool place after cleaning and disinfection. Keep the room temperature between 50–64°F (10–18°C) if you plan to store for more than a week. Maintain humidity at 70–80% to prevent water loss from chicken eggs during storage. Avoid condensation on surfaces to stop bacteria from spreading. Check all parts for damage before the next incubation. Replace worn sensors or trays. Regular maintenance helps you raise healthy chicks and supports successful hatching for chicken and other poultry. Good storage habits also protect your equipment for future rounds of raising baby chicks.

Tip:

Keep your incubator covered when not in use. This keeps dust and pests away from your chicken and poultry equipment.

FAQs—Egg Incubator Manual

You may have questions when you use your eggs incubator manual. Here are answers to some of the most common ones:

- Why do forced-air and still-air incubators use different [temperature measuring points](https://www.eggbloom.com/How-to-Manage-Incubator-Temperature-and-Humidity-for-Successful-Hatching)?

Forced-air incubators have a fan that moves air, so you measure temperature at egg height. The baseline is 99.5°F (37.5°C). Still-air incubators do not have a fan. Heat rises, so you measure at the top of the eggs. The correct range is 101–102°F (38.3–38.9°C). - Humidity looks normal, but chicks stick to the shell. How do you check using weight loss and air cell size?

You should weigh a sample batch at the start and again on day 18. Eggs should lose about 12% of their starting weight. Candle eggs to check air cell growth. If weight loss or air cell size is off, [adjust humidity](https://www.eggbloom.com/10-Must-Know-Tips-for-Incubating-Chicken-Eggs-Successfully) or ventilation. This method helps you fine-tune your settings. - How do altitude and seasons affect temperature, humidity, and ventilation?

High altitude means thinner air, so you need more ventilation. Dry seasons may lower humidity, so add water surface or use a damp sponge. Hot weather can raise room temperature. Always keep the incubator away from direct sunlight and drafts. - What if you cannot see inside thick-shelled or speckled eggs during candling?

Use a strong LED candler in a dark room. Hold the egg with the large end up. If you still cannot see, rely on weight loss and air cell size to track development. Record your findings and adjust your process for the next batch. - How often should you calibrate thermometers and hygrometers? What is a simple way to check?

You should calibrate before each batch. Place two sensors at egg height, away from heating elements. Compare readings. For a quick check, use a medical thermometer or a salt test for humidity. Reliable instruments help you follow your egg incubator manual for better results.

Tip:

Always place sensors at egg height and away from direct heat. Double-check readings with two devices.

Note:

Adjust humidity by changing water surface area, not just by adding water. Stable room conditions help you get better hatch rates.

Gentle CTA—Complete Guide to Incubation

You have learned the key steps for setting up and running your egg incubator. Now, you can put this knowledge into action and start your own hatching journey. You do not need to be an expert to get great results. You just need to follow the basics, keep good records, and adjust your process as you learn.

Tip:

Always record your temperature, humidity, and turning schedule. Review your notes after each batch. Small changes can make a big difference.

Here is a quick summary of what you need:

- Preheat your incubator for 24–48 hours before loading eggs.

- Use forced-air baseline temperature of 99.5°F (37.5°C).

- For still-air incubators, measure at the top of the eggs: 101–102°F (38.3–38.9°C).

- Keep humidity at 45–55% RH for days 1–18. Raise to 65–70% RH for the last three days.

- Turn eggs 3–5 times daily, rotating at least 90°. Stop turning three days before hatch.

- Track egg weight loss. Aim for about 12% by day 18. Adjust humidity using water surface area and check air cell size.

- Increase ventilation as embryos grow. During hatch, keep the lid closed and maintain good airflow.

Safety Reminder:

Place sensors at egg height, away from direct heat. Use two devices to confirm readings. Adjust humidity by changing water surface area, not just adding water.

You can find more guides, diagrams, and tips in our incubation guides and egg incubator resources. If you want to hatch larger batches, check out our cabinet incubator options.

Ready to start?

Download your printable checklist and keep it nearby for every hatch. You can raise healthy chicks by following these steps and learning from each experience. Good luck with your incubation adventure! 🐣

Printable Checklist—Eggs Incubator Manual

Use this checklist every time you set up and run your egg incubator. Print it out and keep it near your incubator for quick reference. You can check off each step as you go.

Preparation

- Unbox and check all parts.

- Place incubator on a level surface, away from sunlight and drafts.

- Calibrate thermometers and hygrometers. Use two devices for accuracy.

- Preheat incubator empty for 24–48 hours. Stabilize temperature and humidity.

Loading Eggs

- Store eggs at 55–60°F (12–15°C), 70–75% RH before incubation.

- Rest shipped eggs for 12–24 hours. Mark batch numbers.

- Place eggs large end up, same height, spaced evenly. Avoid heater area.

- Start incubation within 7 days of collection.

Baseline Settings

| Incubator Type | Temperature | Humidity (Days 1–18) | Humidity (Last 3 Days) |

|---|---|---|---|

| Forced-air | 99.5°F (37.5°C) | 45–55% RH | 65–70% RH |

| Still-air | 101–102°F (38.3–38.9°C) at egg top | 45–55% RH | 65–70% RH |

Daily Operation

- Check temperature and humidity at egg height.

- Turn eggs 3–5 times daily, rotate ≥90°. Stop turning 3 days before hatch.

- Adjust humidity by changing water surface area. Use sponges or cloth strips if needed.

- Increase ventilation as embryos grow.

Monitoring

- Candle eggs on days 7, 14, and 18. Remove non-viable eggs.

- Track egg weight loss. Aim for 12% by day 18. Adjust humidity if needed.

- Check air cell size during candling.

Hatch & Emergency

- Raise humidity to 65–70% RH for last 3 days.

- Keep lid closed during hatch. Open only if necessary.

- If power outage occurs, wrap incubator with dry towels and add warm water bottles. Restore settings slowly after power returns.

Safety Tips:

Place sensors at egg height, away from direct heat.

Adjust humidity by water surface area, not just water volume.

Keep room conditions stable.

Record all settings and changes. Review and adjust for next batch.

Ready to hatch? Print this checklist and follow each step for reliable results! 🐣

You can achieve reliable poultry hatching by following each step in your incubation process. Start with careful setup, daily checks, and safe operation. Always monitor temperature and humidity at egg height. Clean and store your poultry incubator after each hatch to prepare for future use. For more tips, check out our egg incubator, incubation guides, poultry incubator, and cabinet incubator resources.

Tip: Download the printable checklist to guide you through every stage of poultry incubation.

FAQ

Why do forced-air and still-air incubators use different temperature measuring points?

You measure temperature at egg height in forced-air incubators because the fan keeps heat even. In still-air incubators, heat rises, so you check at the top of the eggs. Forced-air baseline is 99.5°F (37.5°C). Still-air needs 101–102°F (38.3–38.9°C) at the egg tops.

Tip: Always place sensors at egg height and away from heating elements.

Humidity looks normal, but chicks stick to the shell. How do you check using weight loss and air cell size?

You weigh a sample batch at the start and again on day 18. Eggs should lose about 12% of their starting weight. Candle eggs to check air cell growth. If weight loss or air cell size is off, adjust humidity or ventilation.

Note: Combine weight loss and air cell size for best results.

How do altitude and seasons affect temperature, humidity, and ventilation?

High altitude means thinner air, so you need more ventilation. Dry seasons may lower humidity, so add water surface or use a damp sponge. Hot weather can raise room temperature. Keep the incubator away from direct sunlight and drafts.

| Factor | What You Should Do |

|---|---|

| High Altitude | Increase ventilation |

| Dry Season | Add water surface area |

| Hot Weather | Keep away from sunlight |

What if you cannot see inside thick-shelled or speckled eggs during candling?

You use a strong LED candler in a dark room. Hold the egg with the large end up. If you still cannot see, rely on weight loss and air cell size to track development. Record your findings and adjust your process for the next batch.

Tip: Always candle quickly to avoid cooling eggs.

How often should you calibrate thermometers and hygrometers? What is a simple way to check?

You calibrate before each batch. Place two sensors at egg height, away from heating elements. Compare readings. For a quick check, use a medical thermometer or a salt test for humidity. Reliable instruments help you follow your egg incubator manual for better results.

- Calibrate before every batch.

- Use two devices for accuracy.

0 Comments